Cold pressing

Cold-pressed oils are pressed without the use of high temperatures typically at about 60°C. After pressing the oil is filtered, resulting in edible oil with a delicate nutty flavour and golden colour. The oil contains soluble vitamins present in the original raw material (vitamin E in particular), unsaturated fatty acids, antioxidants and other nutrients. The natural flavouring substances retained in the cold-pressed oil are very important to the flavour of the oil. The disadvantage of cold pressing is lower pressing yield, which is why the two-stage pressing is used. Its advantage is of course higher yield, but also a substantial saving of wear of the first-stage pressing sets.

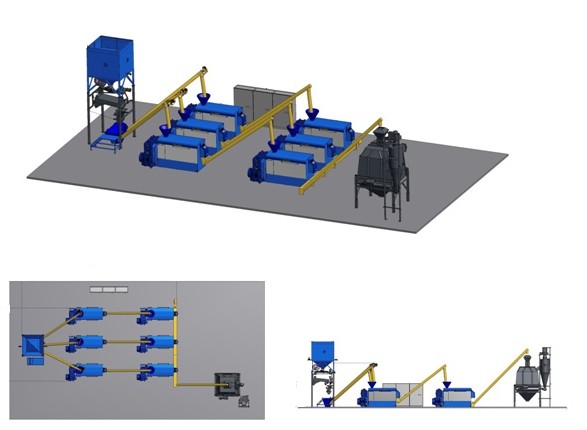

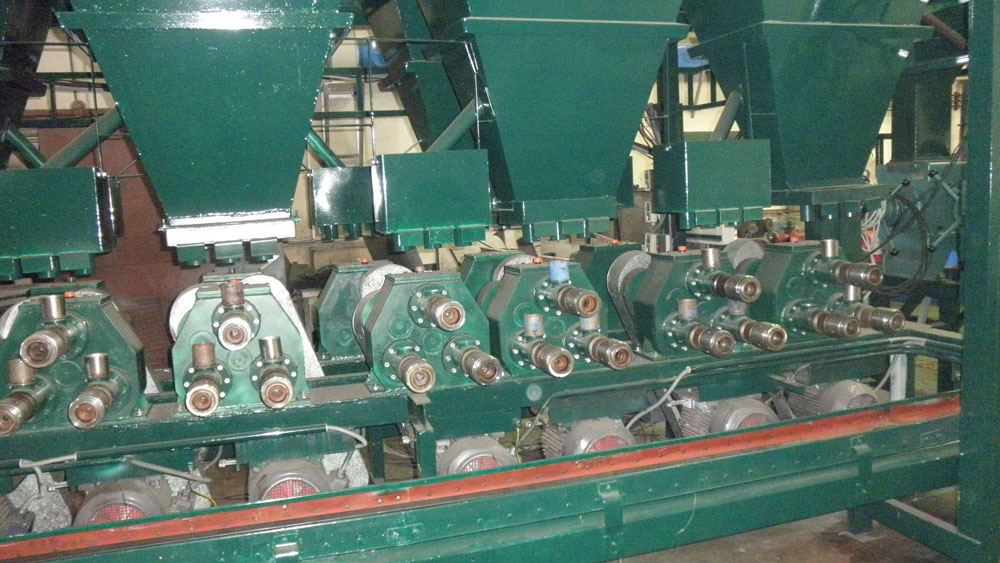

Description of two-stage cold pressing:

The seed at the inlet of the press is passed through a magnetic separator of metal bits. It is then transported to the pre-press for the first-stage pressing. The oilcakes are then transported to the next press, where the pressing of the seeds is finished. The pressed oil is collected in the collecting receptacle with stirrer, from which it is then pumped to the filter press. Oilcakes from the presses are then removed from the press.

Technological supplies to the press starts with the screw conveyor above the hopper for the pre-press and ends with the cake dropping out of the second press. Oil from pre-press and the second press is then collected in a collecting tank equipped with a sludge pump. The sludge pump pumps the oil to the homogenisation vessel, to ensure the pre-press is uniformly dispersed. From the homogenisation vessel the high-pressure screw pump pushes oil through the filter press into storage tanks.

Pressing parameters:

Input parameters

| Oilseeds | Max. humidity for storage | Average humidity recommended | Average oil content with average humidity | Oil content range of effective compressibility |

| Rapeseed | 8% | 6,5% | 42% | 38 – 44% |

| Sunflower | 8% | 6,5% | 43% | 40 – 48% |

Seeds with oil content outside the range of the effective pressing indicated in the table can also be pressed but we expect deterioration of the parameters or problems with the formation of the pre-press and process stability.

Output parameters

Pressing quality is best characterised by the residual fat in the oilcakes (the proportion of oil in the oilcake in percentage) and is given calculated with a 10% moisture content of the oilcakes moisture. Usual values achieved are given in the table, subject to the quality of the input seeds.

| Oilseeds | Residual fat in the oilcake with moisture content of 10% | Residual fat in dry matter (%) | Recovery (%) | Residual oil in the oilcake in % (oiliness – recovery) |

| Rapeseed | 10 – 12 % | 11,1 – 13,3 | 34,08 – 35,56 | 6,44 – 7,92 |

| Sunflower | 10 – 12% | 11,1 – 13,3 | 35,23 – 36,69 | 6,31 – 7,77 |